And them we are going to victimization the below tools to create these cuts:

1.Drill Bits

2.Center Punch (optional)

3.Drag Washer Grease

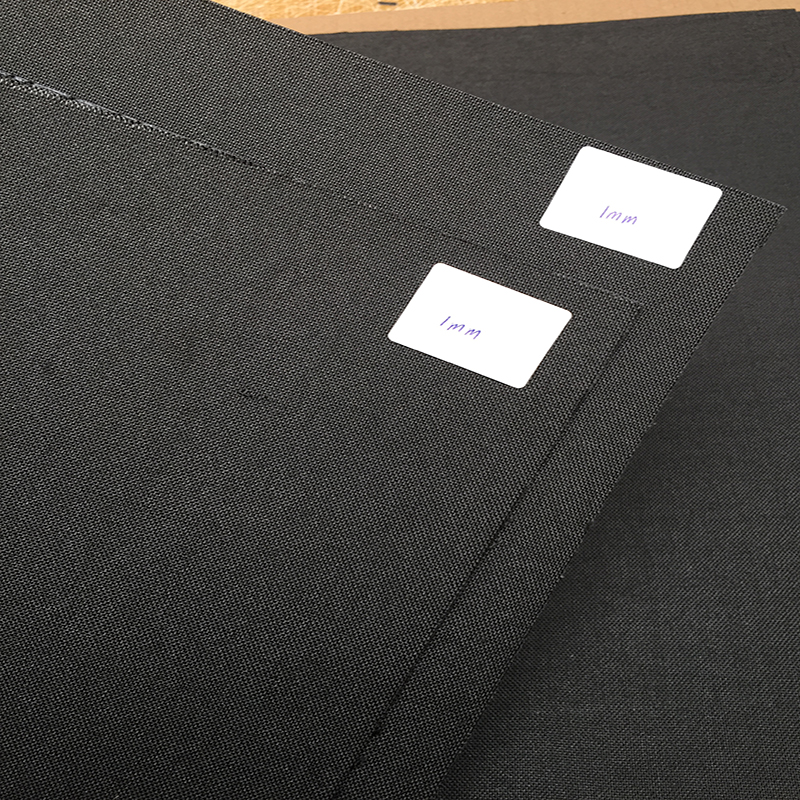

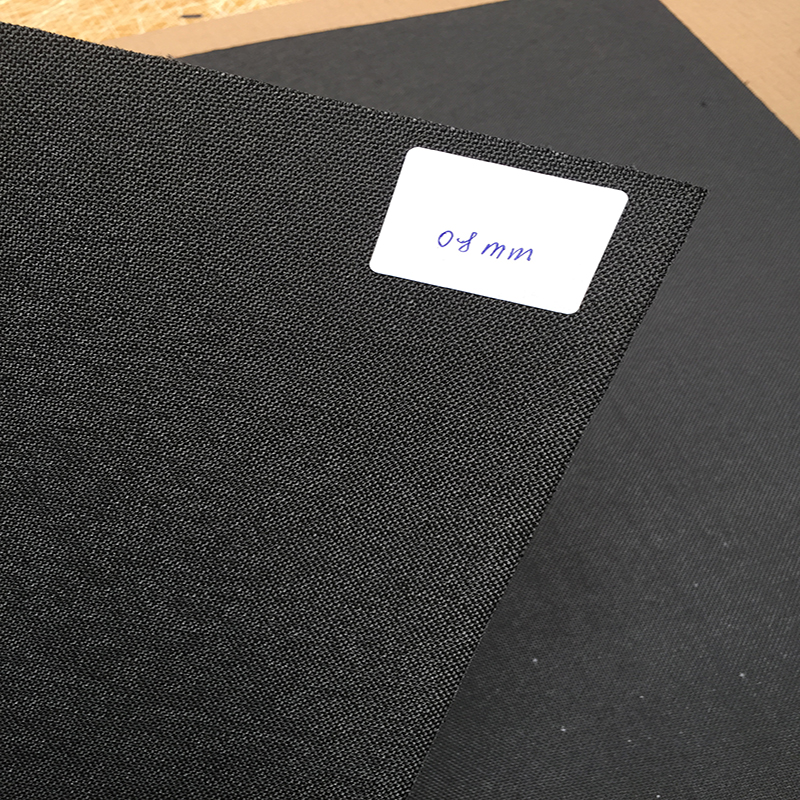

Then, trim off a strip of fabric slightly wider than the diameter of the initial drag washers and long enough to create enough squares of fabric for the number of drag washers you wish. you wish the squares of fabric to be slightly larger than your original drag washers.

Now,you will got to realize a bit that's a decent slot in the middle hole of your previous drag washers. that's the scale that you just can use to drill the middle hole of your new drag washers. victimization associate degree previous drag washer as a guide, thrust the Carbontex sq. as on the brink of the middle of the outlet within the previous washer as you'll be able to. If you are doing not have a middle punch, mark the spot wherever you'll be drilling your hole and use caution once orientating your bit to the mark.

Now you're able to drill your hole. I even have found that it's abundant easier to urge a clean hole trainedwithin the Carbontex material if you run your hammer in reverse. once running forward, the bit can need to poke into and twist the fabric which may build the holes raggedy trying. If you drill the outlet with the drill running in reverse, you'll find yourself with a far cleaner center hole for your new washers.

The first exposure during this step shows my previous drag washer on a screw. As you'll be able to see the screw head is that the same diameter because the outside diameter of the previous drag washer. The washer is additionally a decent enough work on the screw that the washer should be rib onto the screw. whereas all of this is not 100 percent necessary to create your own carbon drag washers, it's improbablyconvenient. The tight work on the screw can are available handy on succeeding step additionally the} diameter of the screw head also is a guide for shaping the new washers. At a minimum, you'll need to use a screw that's terribly on the brink of constant size because the diameter of the inner hole of your drag washer. within the example shown i used to be ready to use the screw head as a guide to chop the washer to its rough final form victimization scissors. If you're ineffectual to search out a screw with a head which will work as a guide for trimming the new washer, use the previous washer as your guide by putting in it on the screw next to what is going to be your new washer and cut the fabric to its rough form with scissors.

For final shaping, we have a tendency to area unit reaching to chuck our screw with the new washer material into a drill (I am employing a shaper here however a drill can work simply fine for this) and use a fine toothed file to file the washer to its final form whereas spinning the screw within the drill. If your washer was a decent enough work that it had to be rib onto the screw, you'll be able to run the hammer inreverse and (using a lightweight bit with the file) the fabric can tighten against the screw head, lockup it in place/keeping it from spinning, whereas filing it to form. If your washer wasn't a extremely tight work onto the screw, you'll got to tighten a nut onto the fabric to stay it from spinning on the screw whereas filing.

Post time: Oct-17-2018