With extremely stiff but lightweight structure, carbon fiber tube is not more fine for enthusiasts and industry professionals, which are widely used in any fields that has a significant need for weight reduction, such as bicycle carbon fiber pipe guard,brackets, aerospace beams, racing structural components, leisure sports and kayaking paddles. Its lightweight and high-strength properties enable it to replace materials such as steel and aluminum.

With extremely stiff but lightweight structure, carbon fiber tube is not more fine for enthusiasts and industry professionals, which are widely used in any fields that has a significant need for weight reduction, such as bicycle carbon fiber pipe guard,brackets, aerospace beams, racing structural components, leisure sports and kayaking paddles. Its lightweight and high-strength properties enable it to replace materials such as steel and aluminum.

Carbon fiber pole are also suitable for the industry which need large bending stiffness, such as automated robots, telescopic rods, rollers and UAV components. In addition, these carbon fiber tube connectors can be manufactured with high modulus carbon fibers such as T700 materials, and their appearance colors can be adjusted according to the color of their surface weaving.

The manufacture of hollow carbon fiber trekking pole may be difficult because pressure is required both inside and outside the laminates. The inner wall thickness is customized according to demand. If you can't find the size you need in the specification sheet, please get in touch with us.

1. How to produce carbon fiber tubes over 2 meter length?

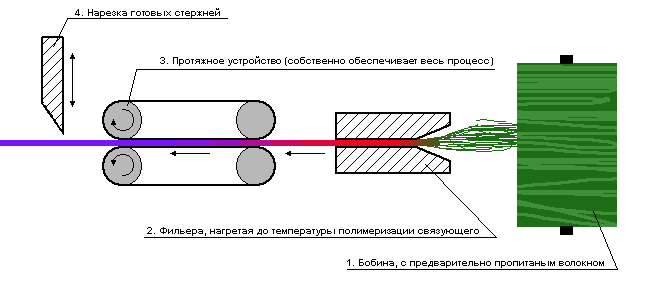

Pultrusion allow to producing carbon trekking pole for almost any length, as long as your workshop area is large enough. In pultrusion, most fibers will run in the same direction, which makes the carbon fiber buffer tube with huge stiffness, but does not too much ring strength.

2. How to improve strength and performance in all directions of carbon tubes?

In order to improve the strength and performance of all directions, Filament Wound is an effective method to manufacture carbon pole. This way of production is low cost, excellent performance, but is the length is limited.

Post time: Dec-19-2018